Increase profitability of a leading vehicle-parts manufacturer

Increase profitability of a leading, speciality vehicle-parts manufacturer by automating pre-production planning and scheduling to optimize manufacturing execution.

Intelligent Digital Worker (IDW) opening invoices in Excel, auditing them and finally making payments to vendors in Quickbooks

Background

The Production Planning Team, at a leading manufacturer of roll-up doors and LED lighting modules for vehicles, is tasked with:

-

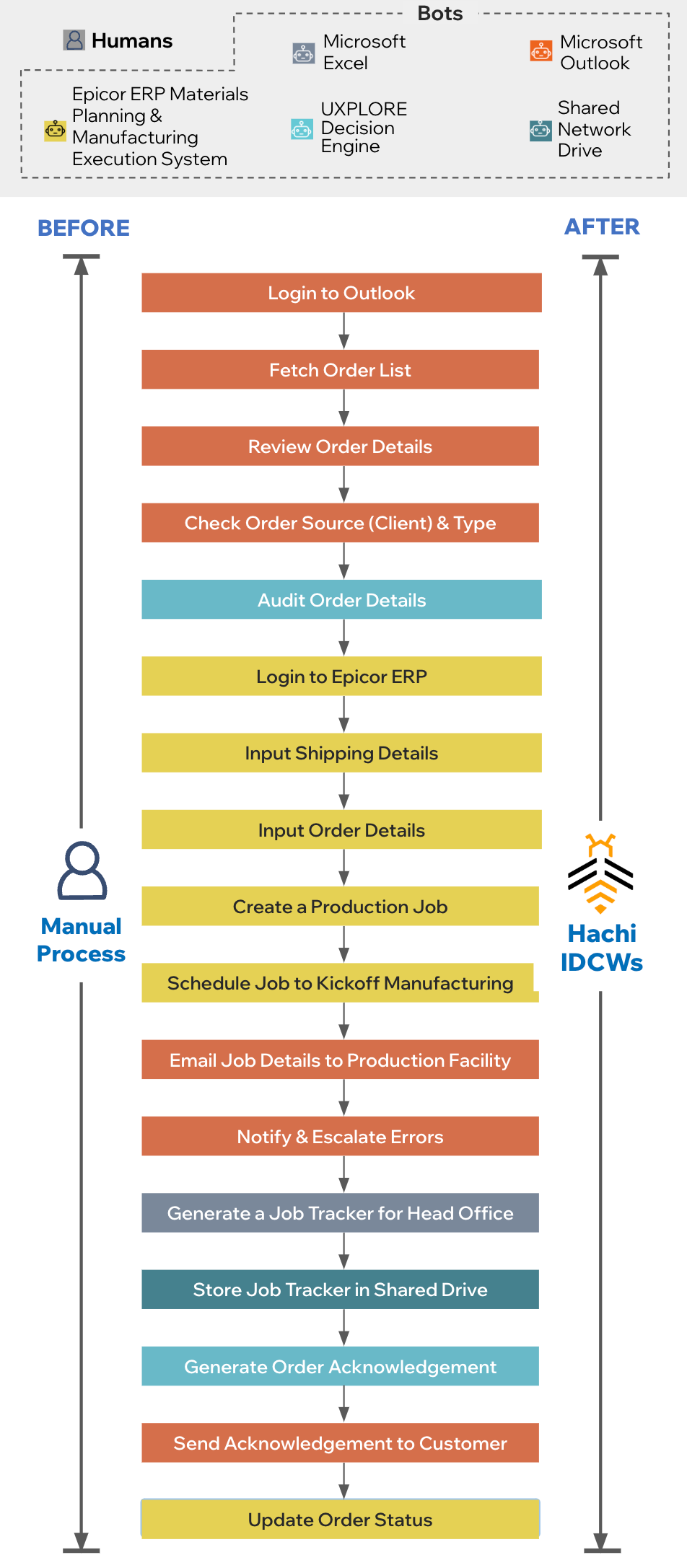

- Receiving purchase orders from via email as PDF attachments.

- Reviewing the list of orders received daily.

- Categorize the orders by clients and types for processing.

- Process the purchase orders in the Epicor ERP system.

- Set up shipping details for the finished products in the ERP system.

- Create a production “Job” in the Epicor ERP for every order entered.

- Optimal scheduling of production Jobs to initiate the manufacturing process.

- Complete order fulfillment processes within client requested timelines.

MAJOR CHALLENGES

-

Complex Decision

Complex Decision Logic across 5 disparate systems

-

24/7 Seasonal Demand

24x7 capacity needed to handle unpredictable order volume, especially over the weekend

-

Manual Entry Errors

Human Errors in production scheduling lead to need for costly manufacturing rework

-

Costly Integration

Multi Million $$ Integration required over 6+ months

SUCCESS

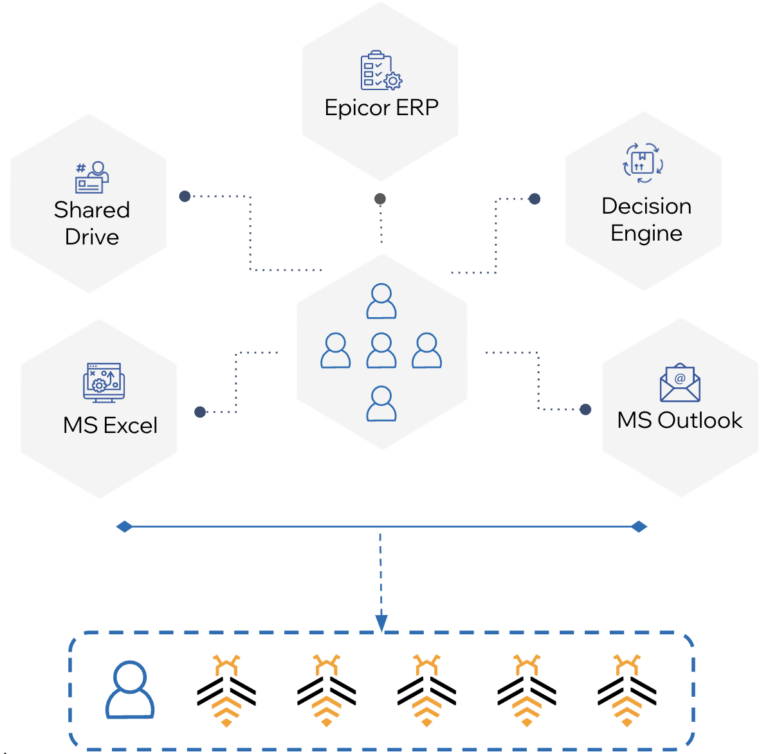

We created agile, non-intrusive bots that seamlessly integrated into existing systems, assisting workers with necessary yet redundant tasks.

This approach ensured:

- 0 new integrations needed

- Immediate Increased Efficiency

- 100% Accuracy

- Assistance 24x7x365

Keys Skills Exercised:

- Multi-Platform Login Access

- Data Reading and Extraction

- Data Entry and Migration

- Searching and sorting

- Reconciliation

- Categorization

- Updates & Corrections

- Error Detection and Escalation

Achieved Results

- 75% Cost Reduction

- 3x Decreased Cycle Time

- 3 Months Payback

- Period ROI from Day 1

- 12 of 14 Tasks Automated

- 1000+ SKUs

- 100+ Daily Orders

APPROACH

Intelligent Digital Co-Workers (IDCWs):

Taking a Hybrid Workforce approach, the IDCWs were created with zero coding by stitching 15+ existing microskills in a calculated and coordinated fashion. They seamlessly emulate human actions and perform tasks efficiently, across existing applications without the need for any custom software development or costly system integrations effort.

ABOUT HACHI

Jahan Ali / jahan.ali@hachiai.com

HACHI is a Hyper Automation platform for training Digital Co-Workers (Bots) to automate complex workflows as per job descriptions using a no-code approach. All possible human gestures and actions are pre-coded and readily available to read, interpret, write & transform data, make decisions and even manage escalations. Alongside the existing team, these Bots can be rapidly trained to perform tasks just like people, by emulating human actions across existing applications without the need for custom software development or costly system integrations effort on a variety of platforms such as mobile, tablet, web, desktop and even legacy CLI based systems non-intrusively.

Website: https://hachiai.com

Office: 207 Queens Quay West, Suite 320, ON M5J1A7